Electrical Generation and Cogeneración

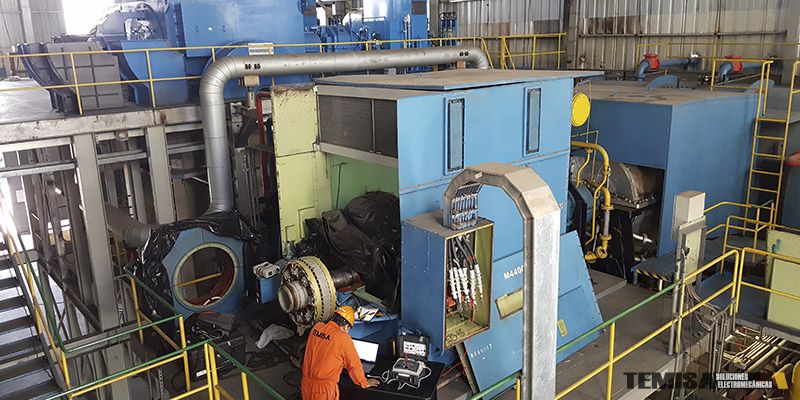

GENERATOR SERVICES

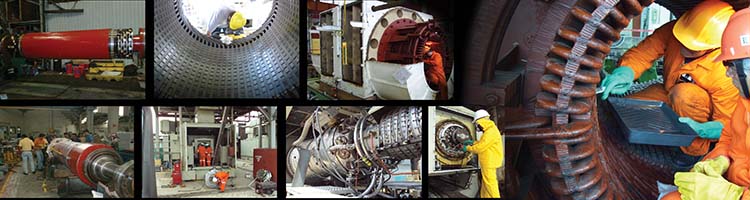

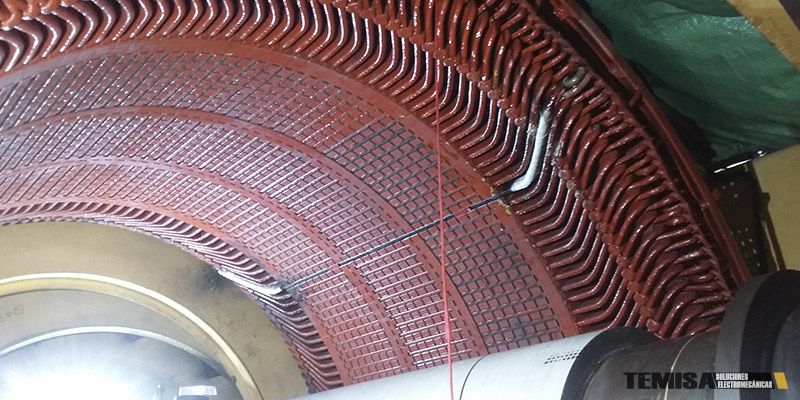

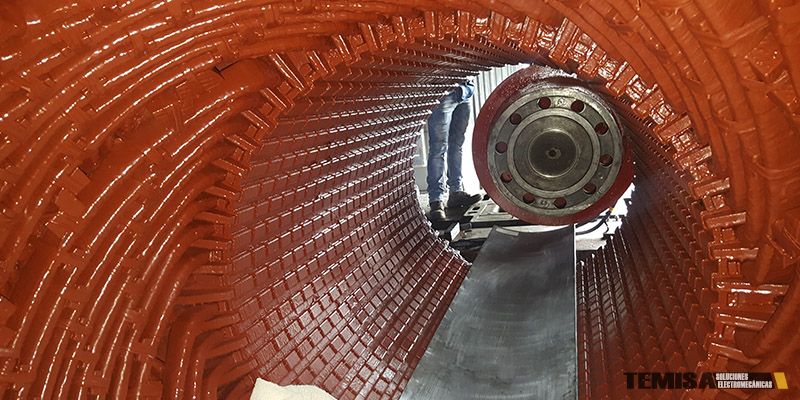

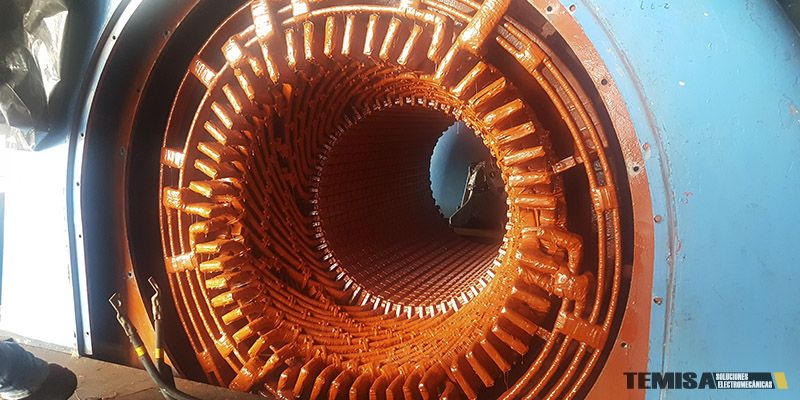

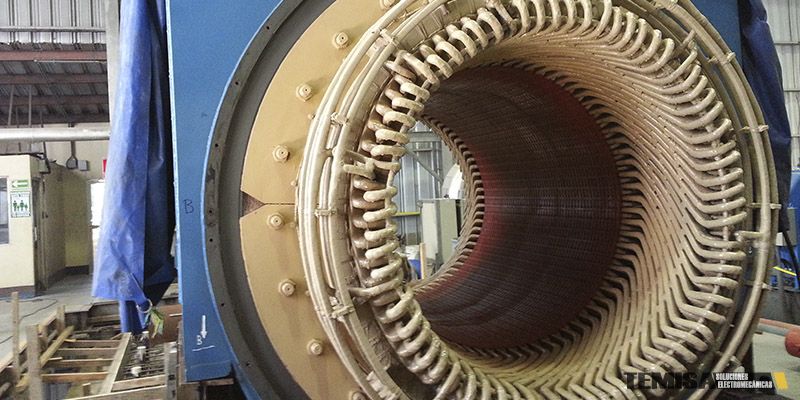

The insulation system is based on the process "Vacuum Pressure Impregnation" (VPI), developed in conjunction with the most renowned suppliers of insulating materials in the world. Using special epoxy resins, this system guarantees the perfect insulation of the winding of the turbogenerators and motors, in a process completely free of emission of gases harmful to the atmosphere. The VPI process for many years has shown its efficiency and reliability in rotating electrical machines in the most varied applications. The insulation system is applied in low and high voltage machines that use preformed coils from 380 to 15,000 V.

All the rotors are dynamically balanced to the turbogenerator operation rotations, in two planes of symmetry. It is performed with computational control of the process, being able to have three degrees of balancing: normal, reduced or special. Increasing the life of the bearings, as well as the turbogenerators and the reduction of the vibration level are some of the benefits of a good balancing.

Scheduled maintenance

Type 1

This type of service is characterized by an operating time of 8,000 hours or at most one year.

Type 2

This type of service is recommended after 25,000 hours or 3 years.

Type 3

This type of service must be carried out after 50,000 hours of service or 6 years.

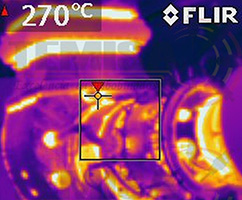

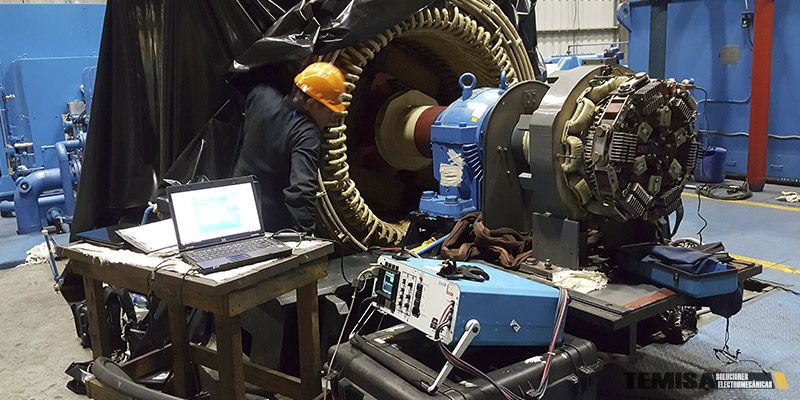

Pruebas eléctricas y mecánicas.

SECTORES INDUSTRIALES

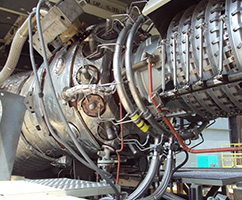

COGENERACIÓN

Bobinado del Rotor

Inspecciones Eléctricas

Inspecciones Mecanicas

Mantenimiento L4

Mantenimiento L4

Mantenimiento L4

Mantenimiento L4

Mantenimiento L4

Mantenimiento L4

Mantenimiento L4

POR COMBUSTIÓN INTERNA

Reparación Eléctrica

Reparación Eléctrica

Reparación Eléctrica

Reparación Eléctrica

HIDROGENERACIÓN

Inspecciones Eléctricas

Inspecciones Eléctricas

Inspecciones Eléctricas

Inspecciones Eléctricas

Inspecciones Eléctricas

Inspecciones Eléctricas

Inspecciones Eléctricas

Mantenimiento a Rotor

Mantenimiento a Rotor

Mantenimiento a Rotor

INGENIOS

Mantenimiento Mayor tipo 4 (L4)

Generador de 5 MVA, Marca: GE Guatemala.

Mantenimiento Mayor tipo 4 (L4)

Generador de 25 MVA, Marca Gevisa. Guatemala.

Remplazo del Rotor

Generador de 71 MVA, Marca JEUMONT. Tlaxcala.

Mantenimiento Mayor tipo 1 (L1)

Generador de 75 MVA, Marca BRUSH. Guatemala.

Mantenimiento Mayor tipo 1 (L1)

Generador de 75 MVA, Marca BRUSH. Guatemala.

Mantenimiento Mayor tipo 4 (L4)

Generador de 25 MVA, Marca Gevisa. Guatemala.

Mantenimiento Mayor tipo 4 (L4)

Generador de 25 MVA, Marca Gevisa. Guatemala.

Mantenimiento Mayor tipo 4 (L4)

Generador de 25 MVA, Marca Gevisa. Guatemala.

Mantenimiento Mayor tipo 4 (L4)

Generador de 25 MVA, Marca Gevisa. Guatemala.